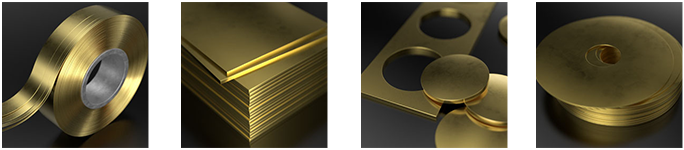

CuZn30 Deco

BRASS

Cu69-71 Zn reste Pb 0.0035 max

| Chemical composition |

|---|

Cu69-71

Ni0.015 max

ZnBAL

Pb0.0035 max

Sn0.015 max

Fe0.015 max

S0.0012 max

| Alloy name | |

|---|---|

| RLSA no. | 331 |

| EN standard | ENCW505L |

| DIN standard | |

| UNS no.* | C26000 |

*Unified Numbering System (USA)

Characteristics and main uses

Special CuZn30 alloy, well suited for decorative parts with high surface requirements, especially after electroplating with Gold, Palladium and Rhodium. The alloy is suitable for diamontage and therefore dedicated for the watch industry, especially hands, dials and other decorative parts.

CuZn30 is a solid solution strengthened copper alloy containing 30% zinc (brass). The alloy has very good cold forming properties.

Main uses

Decorative parts for watch industry, jewelry